Policy

At Aliplast, we employ various policies to achieve our sustainability goals, with a focus on human rights, health and safety. In addition to all our sustainability efforts, we employ various policies that help to achieve these goals.

Human rights

To us, sustainability also means building a just society. We respect human rights in all our operations and provide safe, healthy and fair working conditions. We promote diversity and equal opportunities and only work with partners who share our ethical and sustainable values. By making responsible choices in our supply chain, we support fair working practices worldwide. As a result, we provide products that contribute to a better environment as well as a just society.

It is also important to offer safe, healthy and fair working conditions to our employees, investing in training and welfare. In this way, we form an inclusive corporate culture that fosters innovation and creativity, making for a resilient company.

Health and safety

We continuously invest in protecting our people and optimising our work processes so that everyone can develop in a safe environment. Strict safety standards and health guidelines minimise risks.

Prevention is an important part of our safety policy. Aliplast invests in ongoing education and training for our employees so that they are aware of potential risks and know how to work safely. By sharing best practices and safety procedures, we ensure that everyone is well prepared to function in a safe environment.

Our production facilities and offices are designed to ensure the highest safety standards. From state-of-the-art equipment to ergonomic workstations, we do everything possible to reduce risks and prevent accidents. Regular safety inspections and audits ensure that we continuously improve and address potential hazards quickly. In this way, since 2019, our company has obtained ISO 45001 certification.

ISO certificates

Aliplast is certified according to the leading ISO standards: ISO 9001 and ISO 45001, ISO 14001 and ISO 50001, which highlight our commitment to quality management, environmental friendliness, occupational safety and energy efficiency.

- ISO 9001 confirms our commitment to customer satisfaction and continuous improvement of our processes.

- ISO 14001 demonstrates our commitment to environmentally friendly practices and sustainable business practices.

- ISO 45001 guarantees a safe and healthy workplace for all our employees.

- ISO 50001 highlights our focus on energy efficiency and reducing our carbon footprint.

Responsible procurement

We opt for sustainable procurement by taking into account the social, economic and environmental impact with our suppliers. We work with suppliers who have environmentally friendly and ethical practices. Our efforts with the suppliers have helped lead to a gold Ecovadis medal, placing us among the top 1% of best scoring companies in our sector.

By choosing for responsible procurement, we are committed to a circular economy and contribute to a sustainable future. Therefore, we always check with our suppliers to make sure they meet strict environmental standards and use sustainable production methods. For example, we purchase green packaging material from Ocean Green. This company provides 100% recycled protective material, which is 100% recyclable again after use.

Klimaat- en milieubescherming

Aluminium is een sterk, licht en extreem duurzaam materiaal doordat het 100% recyclebaar is. In tegenstelling tot andere materialen verliest aluminium zijn eigenschappen niet tijdens het recyclingproces, waardoor het eindeloos opnieuw gebruikt kan worden. Ook vraagt het recyclen van aluminium slechts 5% van de energie die nodig is voor de productie van primair aluminium. Aliplast gebruikt voor architecturale systemen een mix aan primaire billets, met een zo laag mogelijk CO2 voetafdruk, en billets van gerecycleerd aluminium. Zo proberen we de aankoop van billets die door bauxietwinning tot stand gekomen zijn te verminderen. Dit is het afgraven van bauxietgronden, waardoor het bestaande ecosysteem wordt aangetast. Ten tweede is het Global Warming Potential (GWP) aanzienlijk lager dan bij primair aluminium.

Climate and environmental protection

Aluminium is a strong, lightweight and extremely durable material because it is 100% recyclable. Unlike other materials, aluminium does not lose its properties during the recycling process, so it can be reused endlessly. In addition, aluminium recycling requires only 5% of the energy required to produce primary aluminium. Aliplast uses a mix of primary billets, with the lowest possible carbon footprint, and billets made of recycled aluminium for architectural systems. In that way, we strive to reduce the purchase of billets created by bauxite mining. This is the excavation of bauxite lands, affecting the existing ecosystem. Secondly, the Global Warming Potential (GWP) is significantly lower than for primary aluminium.

Moreover, the long life cycle of aluminium, over 50 years on average, ensures a positive impact on the environment. The material has long been used in construction due to its energy efficiency, making for energy-efficient buildings. Because aluminium requires little maintenance, it also avoids additional environmental impact during its life cycle.

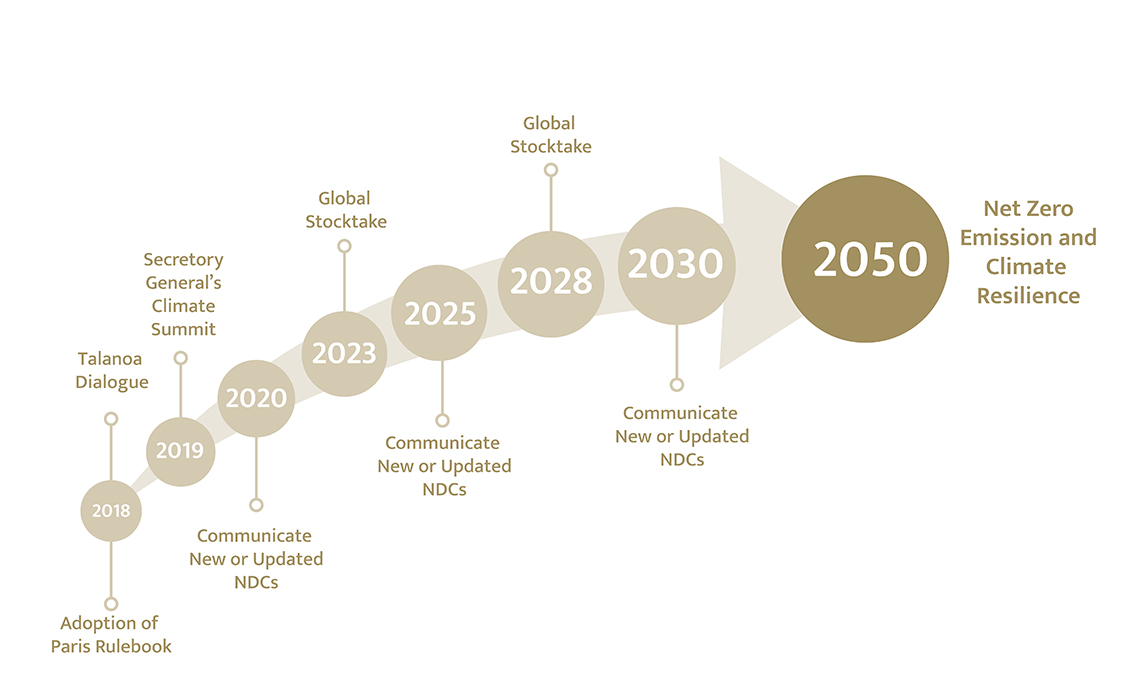

Our sustainability and business goals are in line with the United Nations Sustainable Development Goals (SDGs). We track both our direct and our indirect carbon emissions and take measures to reduce them. Corialis Group has set a target to reduce greenhouse gas emissions by 25.5% by 2030, in line with the Paris climate agreement to limit global warming to no more than 1.5°C.

Waste management

Waste is a by-product created during every stage of the value chain for the production of finished aluminium products. Our approach to waste management starts at the source. By creating innovative and efficient techniques thanks to our years of expertise, we minimise the generation of waste. To achieve this, our key actions are:

- Reducing packaging for internal transport

- Employee awareness campaigns

- Monitoring and assessing waste streams

- Reducing chemicals in our production process

Furthermore, we focus on reusing and recycling materials if we cannot reduce waste. We collect as many waste streams as possible separately, in accordance with VLAREMA legislation, thus reducing the volume that ends up in residual waste. We will also increase the use of reusable packaging and cardboard recycling.

We also believe that it is important for everyone to be trained and be able to correctly put our waste management into practice. To ensure this, a toolbox has been created, which can be consulted via Aliplast's portal and is explained by the departmental managers each time an update is made.

Recyclage aluminium schroot

![[KEY1] [KEY2] [KEY3] [KEY4] [KEY5]](/uploads/nieuws/47/siteschuifraam1.jpg)

![[KEY1] [KEY2] [KEY3] [KEY4] [KEY5]](/uploads/nieuws/49/siteduurzaamheid.jpg)

![[KEY1] [KEY2] [KEY3] [KEY4] [KEY5]](/uploads/nieuws/45/sitegevelbekleding.jpg)

![[KEY1] [KEY2] [KEY3] [KEY4] [KEY5]](/uploads/nieuws/48/siteveranda.jpg)