Circularity

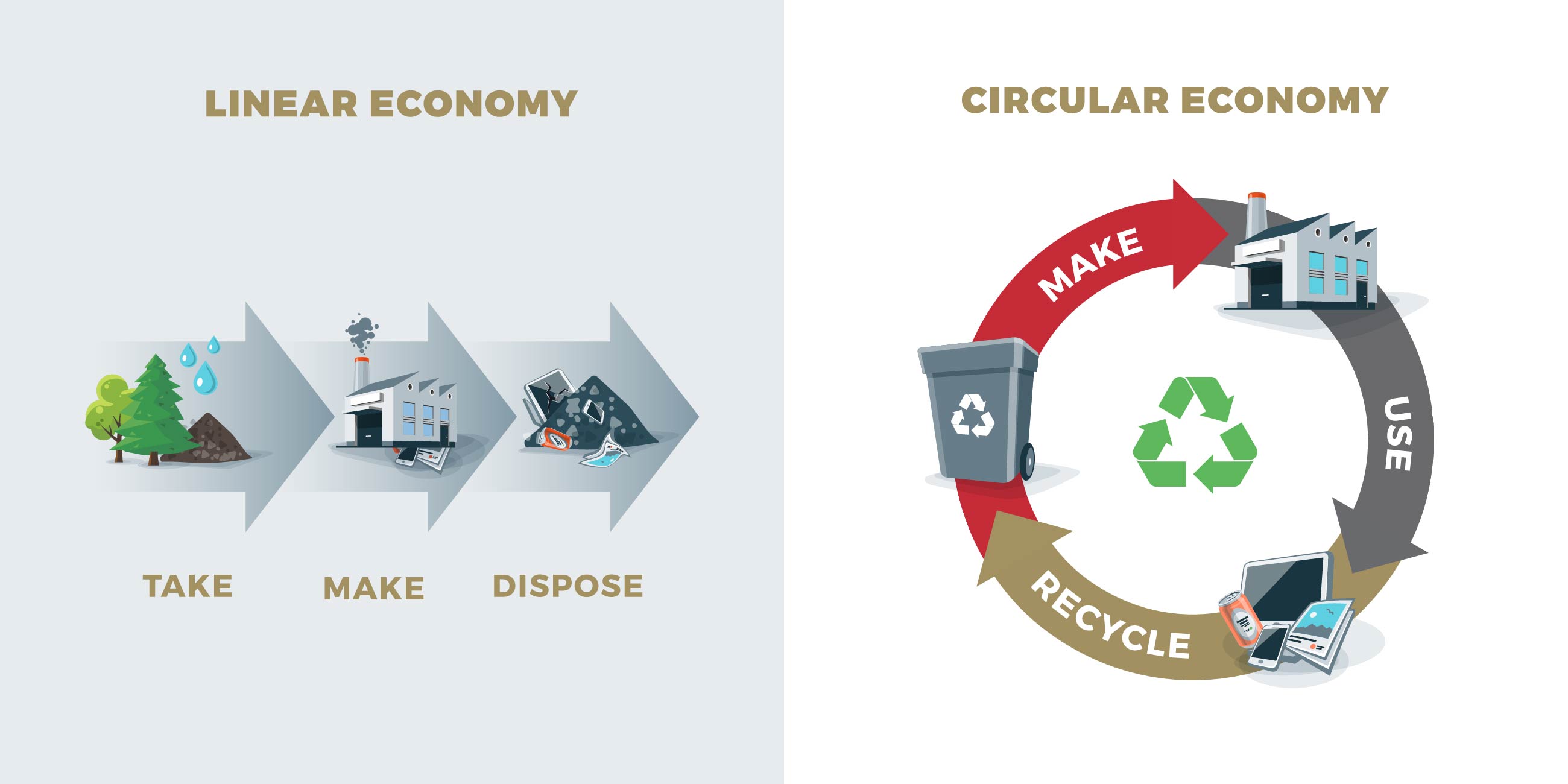

In the future, we are going to have to rely more often on materials that are currently in use; for example, buildings will eventually provide many additional raw materials. Therefore, we must now ensure that as much circular construction as possible takes place. In this way, current materials can be reused, thus closing the production cycle.

100% recyclable

Aluminium, the main component of our window, door and facade systems, is the ideal material in circularity. Not only is it light and strong, but after use it can also be easily re-melted, reformed and reshaped without any loss of quality. Combined with the addition of primary material, aluminium is transformed into so-called recycled billets. Thanks to this property, the profiles are extremely suitable for circular construction. Firstly, this material is excellent for building in accordance with the Cradle-to-Cradle (C2C) principle. Secondly, this material increases the opportunity for buildings to achieve BREEAM certification.

A major advantage of this recycling is that it saves as much as 95% of the energy required to produce primary aluminium from bauxite, leading to a significant reduction in carbon emissions. In Belgium, more than 90% of all aluminium used is recycled again.

Life cycle analysis

At Aliplast, we carry out life cycle assessments (LCA) to identify the environmental impact of our products throughout their life cycle. Various scopes are used within an LCA to indicate the scope of the analysis. At product level, we distinguish the following scopes:

Cradle-to-gate: This includes the production phase of a product, from the extraction of raw materials (cradle) to the moment it leaves the company (gate). This includes production processes and energy consumption.

Cradle-to-grave: This scope goes beyond cradle-to-gate and covers the full life cycle of a product, including its use and final disposal after the end of its life cycle.

Cradle-to-cradle: Within this scope, the finished product can be reused as a raw material for the next product.

Vertical integration

Because vertical integration is perfectly controlled at our Lokeren site, we can more easily carry out analyses on the life cycle of our products in order to optimise them. Because everything is done under one roof, we also ensure that all our products are 100% Belgian.

- Research & development: Aliplast has its own design office with engineers who develop innovative systems in collaboration with various partners. We also have an internal testing facility where we can thoroughly test all our new products.

- Extrusion: We have two extrusion presses (2200T-8 and 4400T-10), which enable us to produce profiles in various sizes and shapes.

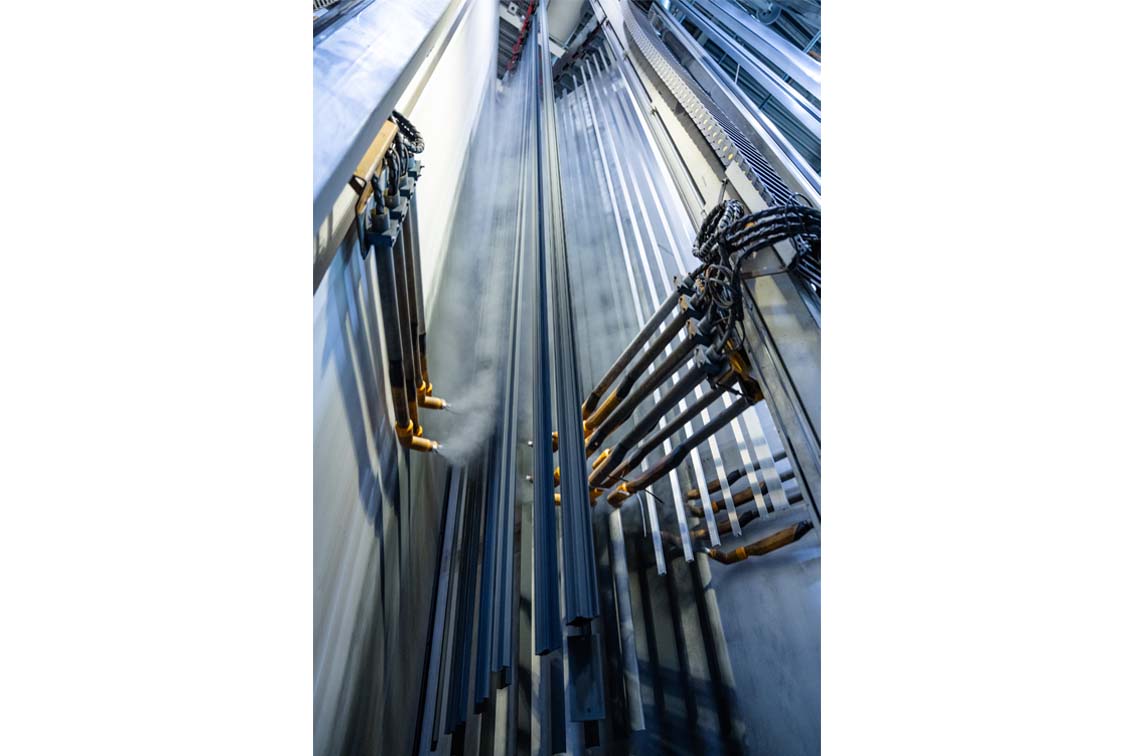

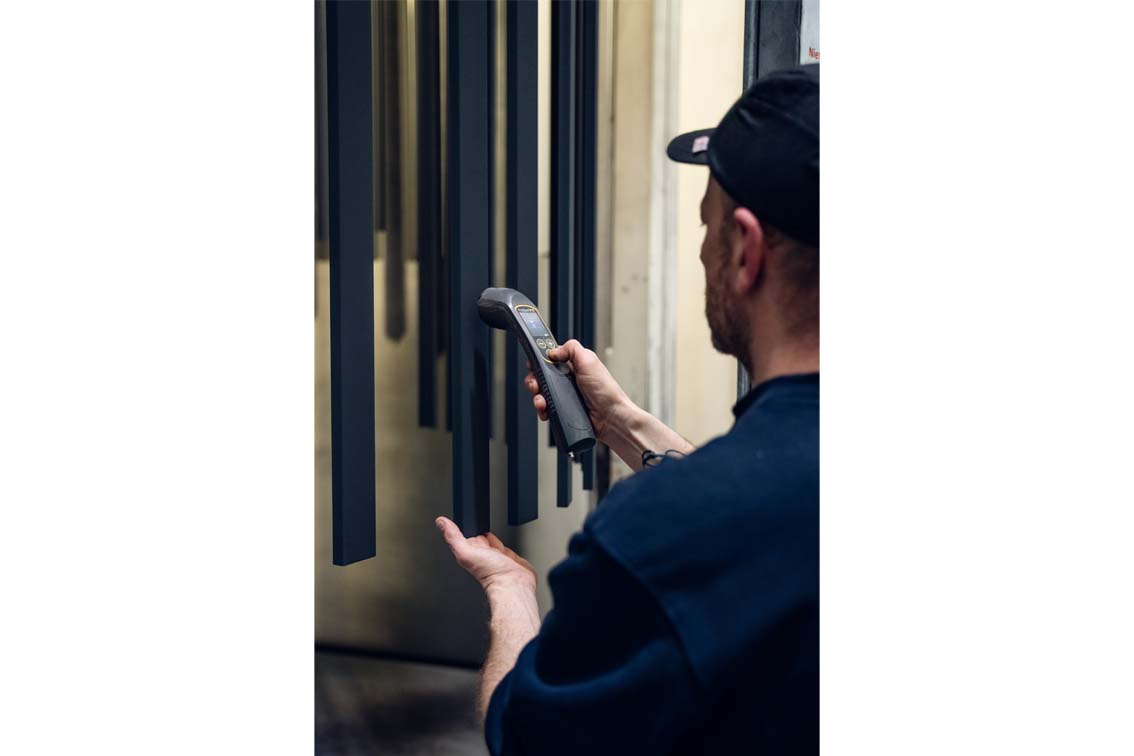

- Paint shop: Our paint shop has three paint lines: a vertical, a horizontal and a service paint line. In addition to profiles, fittings, accessories, bending, sheet metal and folding work are also powder coated on our own lines, entirely according to Qualicoat Seaside guidelines.

- Insulation and packaging: Our fully automated insulation lines provide thermal insulation of profiles. All profiles are packed and transported in reusable metal containers.

- Customisation: Customised bending, folding and punching work is carried out in our specialised department.

Cradle-to-Cradle

This globally recognised C2C certification encourages companies to design safe and sustainable products with the circular economy in mind. C2C differs from traditional reuse in that there is no loss of quality. All of the materials used in a product can be recycled.

To obtain a C2C label, these products are assessed on five key aspects: material health, product circularity, air quality & climate protection, water and land management and social justice. The ultimate goal is to encourage innovation and to design products that have an effective and positive impact on people and the environment.

By constantly innovating, we ensure that our products can make an increasing contribution to a circular economy. Because aluminium is infinitely recyclable, we play a major role as a manufacturer of aluminium profiles. We continuously strive for perfectly reusable components in all our systems. Many of our products therefore have a silver Cradle-to-Cradle certificate:

|

|

By 2023, 47% of our sales were from C2C-certified products.

Characteristics of aluminium

Aluminium is made from bauxite ore, a natural material available in abundance. After extraction and refining, the aluminium can be rolled, cast or extruded. Our finishing profiles also contain no harmful substances. In addition, our new materials are more resistant to temperature fluctuations, thus minimising distortion.

To insulate our profiles, we use environmentally friendly insulation materials, which also have excellent insulating properties. These high insulation values contribute to a home's energy efficiency by keeping the heat in during winter and keeping the home cool during summer. As a result, aluminium profiles help optimise energy consumption. Moreover, aluminium is a very strong material, which makes it suitable for bearing large glass surfaces.

There are also a number of other advantages. Aluminium is very colourfast, especially with the powder coating we apply. As standard, we offer a 15-year colour guarantee and a guarantee of up to 25 years on some coatings. These profiles are also very easy to maintain. With proper care, you only need to treat them a few times a year to keep them in good condition. Both the powder coating and its application on the profiles are regularly tested according to Qualicoat standards, for which we have received a certificate.

Aluminium windows have a very long life cycle, as they last at least 50 years. It is an all-weather resistant material with high corrosion resistance. Thanks to their infinite recyclability, aluminium profiles can therefore go through several life cycles. Currently, 75% of all aluminium ever produced in the world is still used.

![[KEY1] [KEY2] [KEY3] [KEY4] [KEY5]](/uploads/nieuws/49/siteduurzaamheid.jpg)

![[KEY1] [KEY2] [KEY3] [KEY4] [KEY5]](/uploads/nieuws/45/sitegevelbekleding.jpg)

![[KEY1] [KEY2] [KEY3] [KEY4] [KEY5]](/uploads/nieuws/47/siteschuifraam1.jpg)

![[KEY1] [KEY2] [KEY3] [KEY4] [KEY5]](/uploads/nieuws/188/sitekleuren%201.jpg)